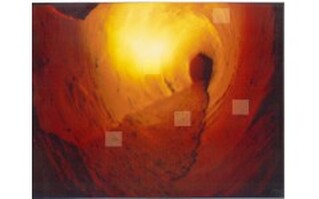

The benefits of operators being able to visually monitor the interior of boilers, furnaces, kilns and other high temperature processes have long been proven. Adding the integrated ability to accurately measure and access process temperature to the video capabilities of the imaging system greatly expands the utility of this high temperature camera technology. SYN-FAB® offers several levels of combining the video from our high temp camera systems with temperature monitoring.

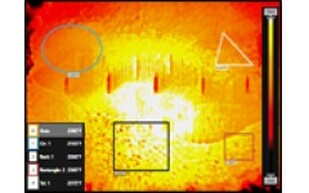

Pyro-Viper™-HDOur Pyro-Viper™-HD is a PC based, software driven image processing and analysis system which allows unlimited target areas to be defined and measured within the field of view of each SF12 series imaging system. A color thermograph of the process area can be generated with this system as well as many other image processing and data analysis functions. Image and data storage, trending, and outputting via several formats are available with the Pyro-Viper™-HD system.

| ||||||||||||||||||||||

Thermal Analyzer IIIThe Thermal Analyzer III is a basic system which allows the operator to define and display up to 4 target areas within the field of view of the imaging system. The average temperature of each target area is displayed on the Thermal Analyzer and is also available as industry standard outputs for connection to other devices or the plant’s DCS.

| |||||||

SPECTRUM™ TGOur SPECTRUM™ TG is an economical and easy to use image processor that will transform the video from your SYN-FAB high temperature imaging system into a calibrated color thermograph. Instead of the typical monochrome infrared image, a temperature defined color image is displayed on the monitor.

| |||||||

Process temperature from 400° F (204°C) to 3300°F (1816° C) can be monitored with the systems depending on the model and calibration ranges selected. The two-color, dual wave-length option of the PYROVIPER system allows for the accurate measurement of temperatures in processes that may become obscured by smoke, dust or particulate. Systems can also be calibrated for flame and/or surface temperature measurement within the processes. All units are factory calibrated to an industry standard heat source and shipped with system specific calibration tables.